- SEKTOR50

- SEKTOR50 PLC Plus

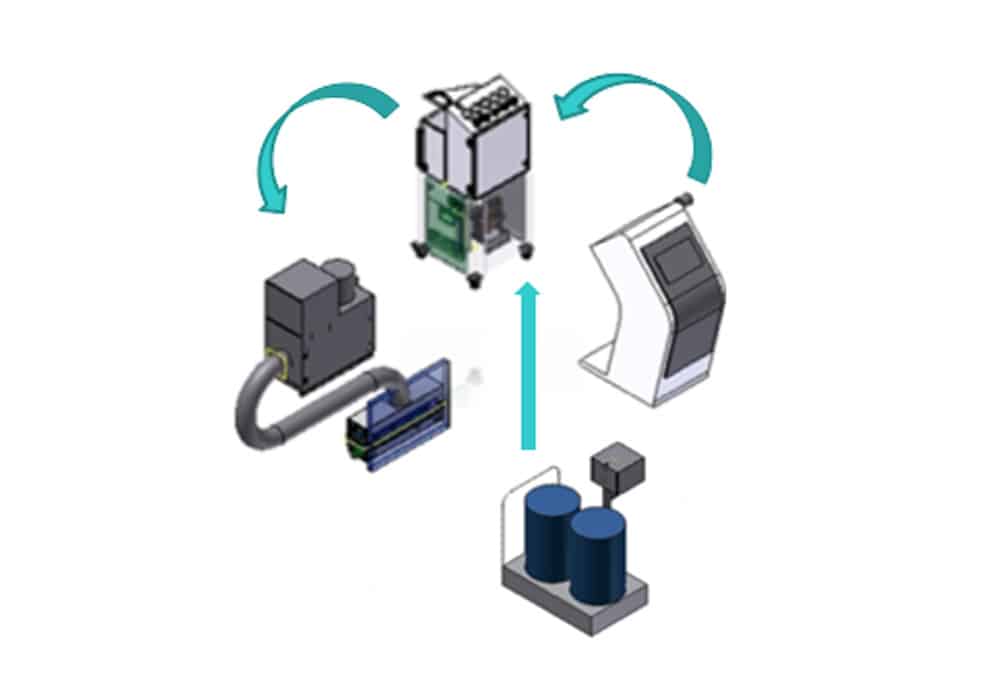

- Motorized SEKTOR50 PLC Plus

- Remoted SEKTOR50 PLC Plus

SEKTOR50 / modelli:

DOWNLOAD

Description

This machinery is born to satisfy the needs of the minimal lubrication in sectors. Its activity is based on a Spray System with carter and guarantees a minimal lubrication for both lower section and top section of coil and square cut. A remoted pulpit provides control and management of the system. The PLC by SIEMENS with TOUCH PANEL operates on activation/deactivation of couples of lubrication points and it defines also the lubrication cycle of activated nozzles, starting from an external start button (a continuous signal, and not a impulsive one wired to the input of PLC).

Applications

It can be used for square cuts and coils lubrication up to 2000 mm width. If the oil used has a high viscosity or if it is subjected to physical/chemical variations because of low temperature, or in countries or plants where the temperatures are quite low; it is possible, as an option, asking for a thermal boundary installation inside the tank to have the lubricant in the best condition.

Advantages

- It’s possible to save the recipes

- The system can operate in small areas

- It’s possible the direct suction from the drum without pouring

- Various types of lubricants can be handled

- Homogeneous and correct lubrication on metal sheets

- Reduction in lubricant consumption

- Increase of moulds lifetime

- Reduction in downtime for machineries

- It possible changing the quantities of lubricants depending on conveyor belt speed

- Immediate control of quantity used on metal sheets

- Easy to use

- Precise and long-lasting machinery