Areas

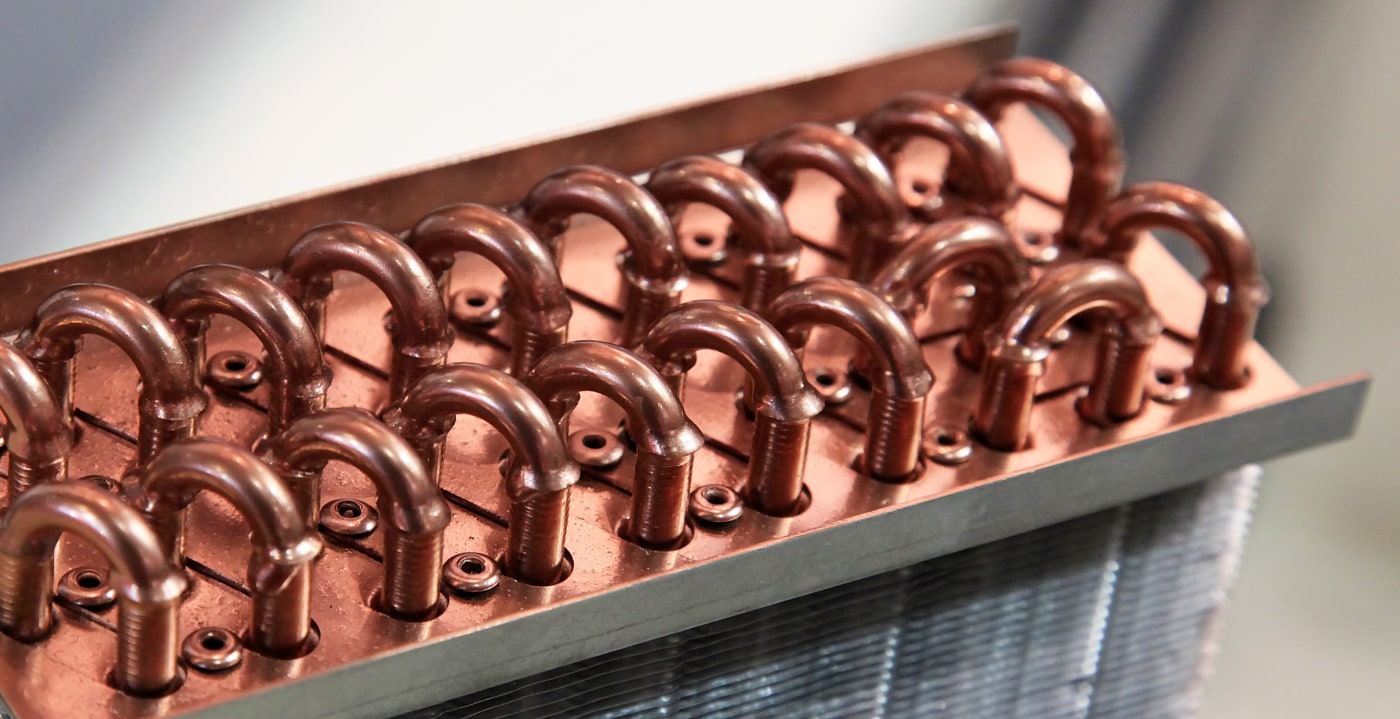

Refrigeration

Specialized in finned pack and plate heat exchangers, we have always operated in the refrigeration field, where lubricants play a crucial role, thanks to fully saturated ester-based products that do not create carbon residue during the coil brazing phase.

LMI in your process

Where we can help you

refrigeration

Areas of use

Manufacture of finned packs for fin molding

Manufacture of finned packs for tube and bend processing

Lubrication for aluminum molding with hydrophilic coating

Machining

- FIN MOLDING

- STAINLESS STEEL PLATE MOLDING

- COPPER PIPE MACHINING

- ALUMINUM PIPE MACHINING

- STAINLESS STEEL PIPE MACHINING

how we work

Customized solutions for every need

At LMI, we take a highly personalized approach to meet the unique needs of each customer.

With LMI, you don’t just get products, you get a true strategic partner by your side every step of the way.

Consultancy

We start with an in-depth consultancy to fully understand your manufacturing challenges and goals.

Company survey

We conduct on-site surveys to directly assess your operations, thus identifying opportunities for improvement and optimization.

Customized solutions

We develop fully customized solutions that integrate perfectly into your production processes, thus ensuring efficiency, safety and sustainability.

manufacturing site

Discover where innovation is born: here is our Plant

Step into the core of LMI and discover how our cutting-edge technology and commitment to sustainability combine to create world-class industrial solutions.

Optimize your production line with the tailor-made solutions designed by LMI

Our team of experts is ready to work with you to analyze your needs and develop effective strategies that improve efficiency, safety and sustainability.

Contact us

"*" indicates required fields